-

PRODUCTS

- CORRUGATED

- TEXTILE

- GARMENT

- EMBELLISHMENT

- SIGNS & GRAPHICS

- INKS

- PRINTHEADS

- MEDIA

-

SUPPORT

-

APPLICATIONS

-

LINKS TV

-

COMPANY

-

PRODUCTS

-

CORRUGATED

-

TEXTILE

-

GARMENT

-

EMBELLISHMENT

-

SIGNS & GRAPHICS

-

INKS

-

PRINTHEADS

-

MEDIA

-

CORRUGATED

-

SUPPORT

-

APPLICATIONS

-

LINKS TV

-

COMPANY

织品数字印花新工艺现已为工业做好准备

New process for digital printing on textiles now ready for industry

by University of Borås

Credit: University of Borås. 布罗斯大学

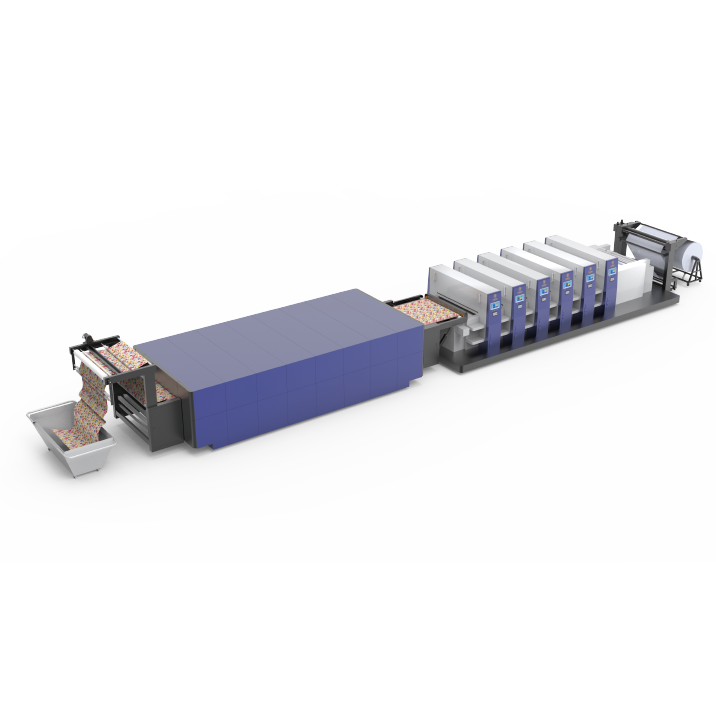

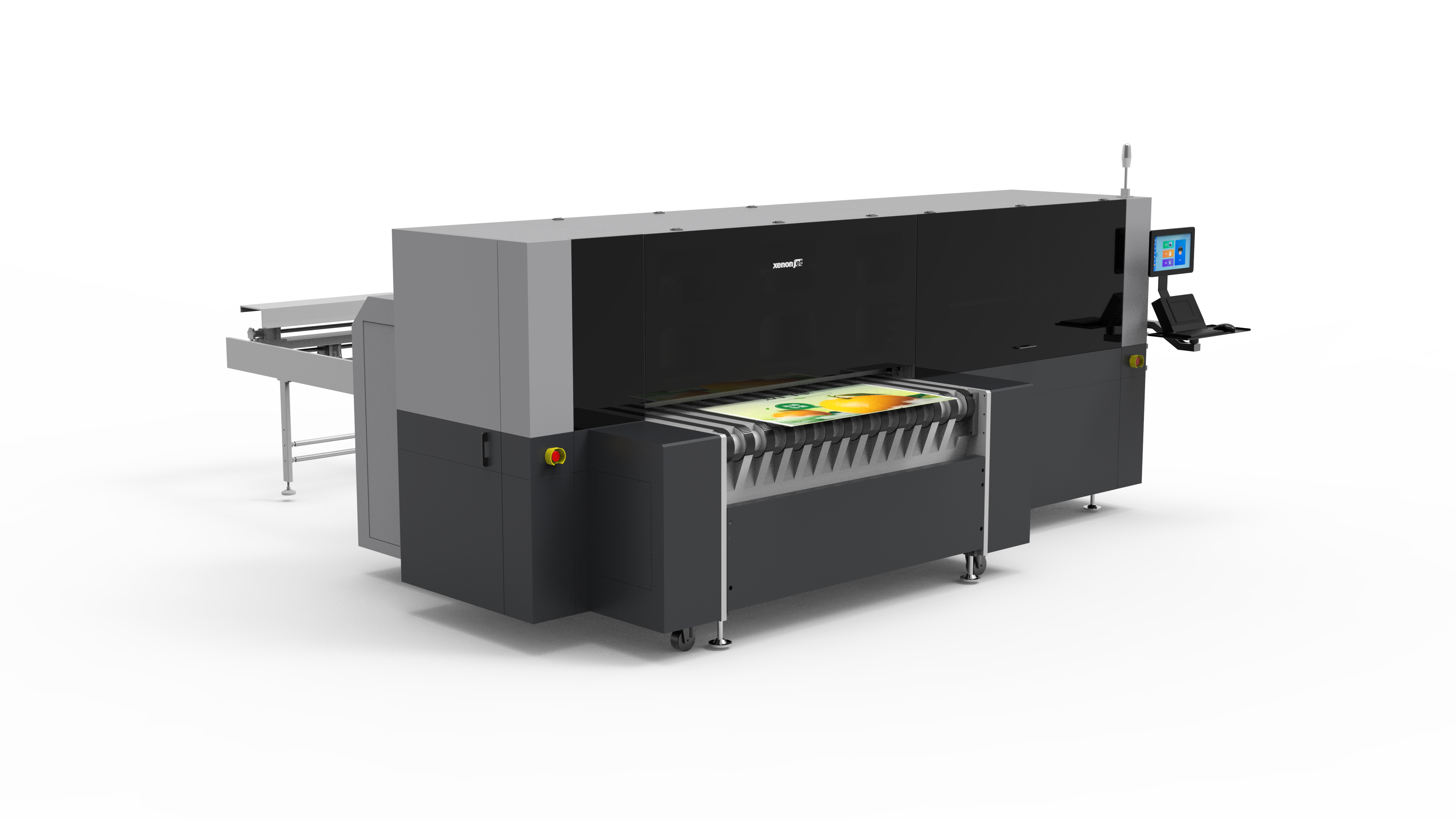

在布罗斯大学的一个研究项目中开发的纺织品数字印刷新工艺现在可以成为纺织行业应对大量水消耗和有害物质排放的解决方案的重要组成部分,该行业对此负有责任。

A new process for digital printing on textiles, developed within a research project at the University of Borås, can now be an important part of the solution for the textile industry to deal with the enormous consumption of water and emissions of hazardous substances, for which the industry is responsible.

该项目的研究人员与各种工业合作伙伴一起优化了印刷技术和工艺,以便通过开发一种新的适应的油漆和墨水配方,使其现在准备在工业规模上使用,该配方适用于工业中使用的打印头和协议。

Together with various industrial partners, the researchers in theproject have optimized the printing technology and process so that it is now ready to be used on an industrial scale by developing a new adapted formula of paint and ink that works in the print heads and protocols used in industry.

在“SusdigiTex——使用功能性服装可持续油墨开发数字印刷工艺”项目中,瑞典纺织学院的纺织材料技术研究小组开发并测试了一种颜料油墨,并将其优化为单色印刷品和图案。他们通过使用不含对环境有害的碳氟化合物的成分来混合和测试防水油墨,这些碳氟化合物被用作浸渍剂,但必须逐步淘汰。

In the project "SusdigiTex—Development of a digital printing process with sustainable inks for functional clothing" the Textile Materials Technology research group at the Swedish School of Textiles has developed and tested a pigment ink and optimized it for single-color prints and patterns. They have mixed and tested water-repellent inks by using components that are free of environmentally hazardous fluorocarbons, which are used as impregnating agents, but which must be phased out.

“有了这项技术,就可以准确地将材料送到您想要的地方,从而可以节省原材料并减少生产后残留的化学品的处理。该项目为在纺织品染色,整理和功能化中实施可持续的数字印花技术设定了标准,“高级讲师兼研究团队成员俞俊春说。

"With this technology, it is possible to get the material exactly where you want it, which makes it possible to saveraw materials and reduce the handling of chemicals that remain after production. This project sets the bar for the implementation of sustainable digital printing techniques in textile dyeing, finishing and functionalization," said Junchun Yu, Senior Lecturer and member of the research team.

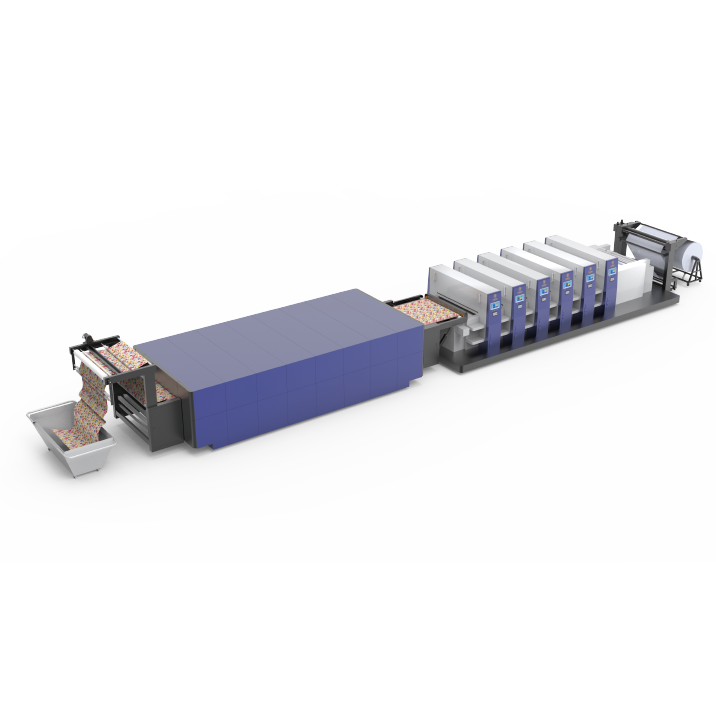

FOV Fabrics AB多年来一直与该大学就数字印刷技术进行多项研究合作。业务开发人员Fredrik Johansson解释说:“与大学的合作有助于我们在十年来的几个研究项目中投资数字印刷技术,资金主要来自知识基金会和Vinnova。我们看到正在进行的研究实际上最终产生了结果,现在我们正在经历能够转向工业规模的必要条件。通过这种方式,我们正在向下一代生产技术迈出一大步,该技术提供了巨大的可持续性效果,几乎不使用水,同时还确保显着减少化学品和能源消耗。

FOV fabrics AB has for many years had several research collaborations with the university regarding digital printing technology. Fredrik Johansson, business developer, explained that "collaboration with the university has contributed to our investing in digital printing technology based on several research projects over ten years with funding mainly from the Knowledge Foundation and Vinnova. We see that the research that is being carried out is actually eventually producing results and now we are experiencing the conditions necessary to be able to move to an industrial scale. Through this, we are taking a big step into the next generation of production technology, which provides great sustainability effects in that almost no water is used while also ensuring that chemical andenergy consumption is significantly reduced."

“数字油漆和印刷技术是全球可持续发展和纺织加工业生存的关键。虽然数字印刷技术正在走向工业化,但这些技术的潜力还需要进一步研究,“俞俊春总结道。

"Digital paint and printing technology is the key to global sustainability and to the survival of the textile processing industry. Although digitalprinting technology is on the way to industrial implementation, the potential of these technologies needs to be investigated even more," concluded Junchun Yu.